Process Description:

The goal for Refrigeration Unit in industrial scale is cooling down of a process stream (vapor or liquid) to a lower temperature, by means of a circulated closed loop. Closed loop circuit, which is called refrigerant, mostly is Propane, Propylene, ammonia, R-134a or other type of gases which selected by consideration of required temperature, environmental situation, availability, cost, …

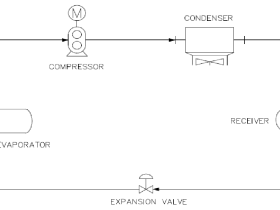

Briefly, each industrial Refrigeration Unit cycle consist of Five main components:

- Evaporator (Chiller), a Kettle Type Shell& Tube Exchanger

- Compressor, Screw or Centrifugal Type

- Condenser, Air Cooler or Water Cooler Exchanger

- Receiver, Pressure Vessel

- Expansion Equipment, mostly Control Valve

The Benefits:

Industrial Refrigeration Units is our expertise. SINA Control is responsible for whole package Design, Fabrication, Delivery and Guarantees.

SINA Control design futures and benefits on refrigeration Unit are:

- Most competitive price due to maximum usage of local equipment and capabilities

- Use of high efficiency Oil Injected Screw Type Compressor (API-619), equipped to internal Slide Valve and by-pass control system, in order to prevent over pressure

- Supply of compressor unit from world-wide/ well known manufacturers

Package is fabricated as modular, therefore it is installed and ready to use in the shortest possible time